Technical

GRP Demountable system

Flexibility of Layout

Due to the truly modular nature of the system, there is a wide range of layout possibilities. The final layout can also be easily modified to suit any future developments or possible rearrangements of an existing layout.

Foundations

Not all sites require foundations, however, this is entirely dependent on ground conditions. Due to the system being lightweight the size of the foundations are smaller than traditional build car parks, time and money are saved

Ramp Design

Our ramps are manufactured from galvanised open grid grate which is not susceptible to dynamic loads in the way that concrete is and therefore cracking to the ramp it eliminated.

The ramps are not affected by adverse weather and do not require de-icing during the winter months.

Control of Rainwater

The deck modules and infill panels are sloped in a single to allow for water to naturally run off to a linear slot line gutter system.

Lighting

The underside light fittings typically give an average 100 lux level. PIR's are incorporated in each fitting which turn on the fittings when required for a set amount of time which is very eco-friendly.

GRP Deck Panels

The surface of the deck is made from a chemical-resistant surface known as GRP. This is a composite material manufactured with an isophthalic resin. The deck finish incorporates a non-slip surface which is created by having carborundum chips embedded into the GRP

These panels have a life expectancy in excess of 50 years and excellent thermal stability capable of withstanding a temperature range of -40 to +150 degrees Celsius.

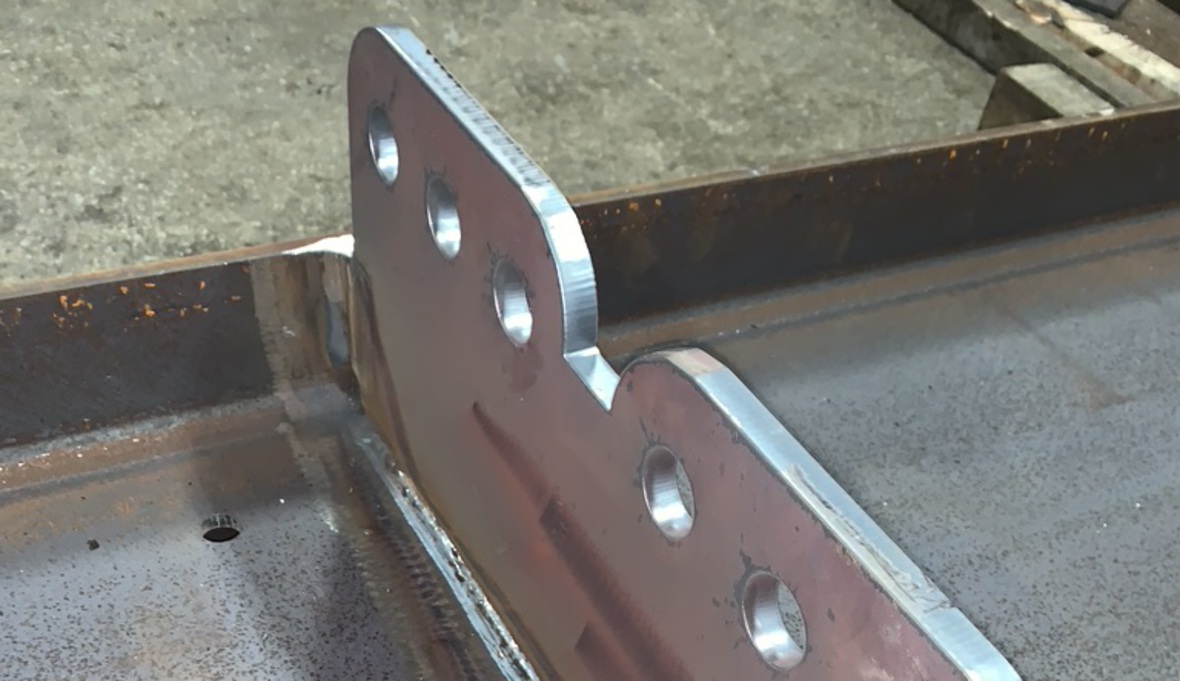

Paint Specification

The protective coating is expected to give a life expectancy of 15+ years to first maintenance as per ISO12944 C3 environment, high durability paining. The longevity can be extended up to 25 years using an enhanced painting system

Modular System Testing

Load testing has been carried out on the composite decking by both Messrs Sandberg and Queen Mary University to provide structural integrity data on the panels under the designed UDL and point load conditions. Fire testing has been carried out by the BRE to ensure the system complies with current building regulations.